The Long-Term Value of Quality Materials: A Comparative Look at Sealants, Coatings, and Flashing

📌 Key Takeaways

Comparing façade restoration bids in Brooklyn? Focus on what delays the next repair cycle and protects the asset’s value.

Labor Dominates Lifecycle Cost: Higher-grade materials extend service life and defer the next mobilization, improving Total Cost of Ownership.

Specify the Sealant Grade: High-performance silicone or pre-cured silicone typically outlasts basic urethanes under UV and movement, cutting premature joint failures.

Demand Breathable Masonry Protection: Penetrating silane/siloxane repellents shed rain while allowing vapor to escape, reducing trapped-moisture risk versus film-forming elastomerics.

Prioritize Flashing Durability and Details: Choose corrosion-resistant metals and verify laps, end-dams, weeps, and continuity to prevent water entry at transitions.

Build Control Into Procurement: Require complete material submittals and manufacturer warranties, and schedule field QA to align promised performance with installation.

Quality materials = longer cycles and stronger TCO.

Time to choose wisely.

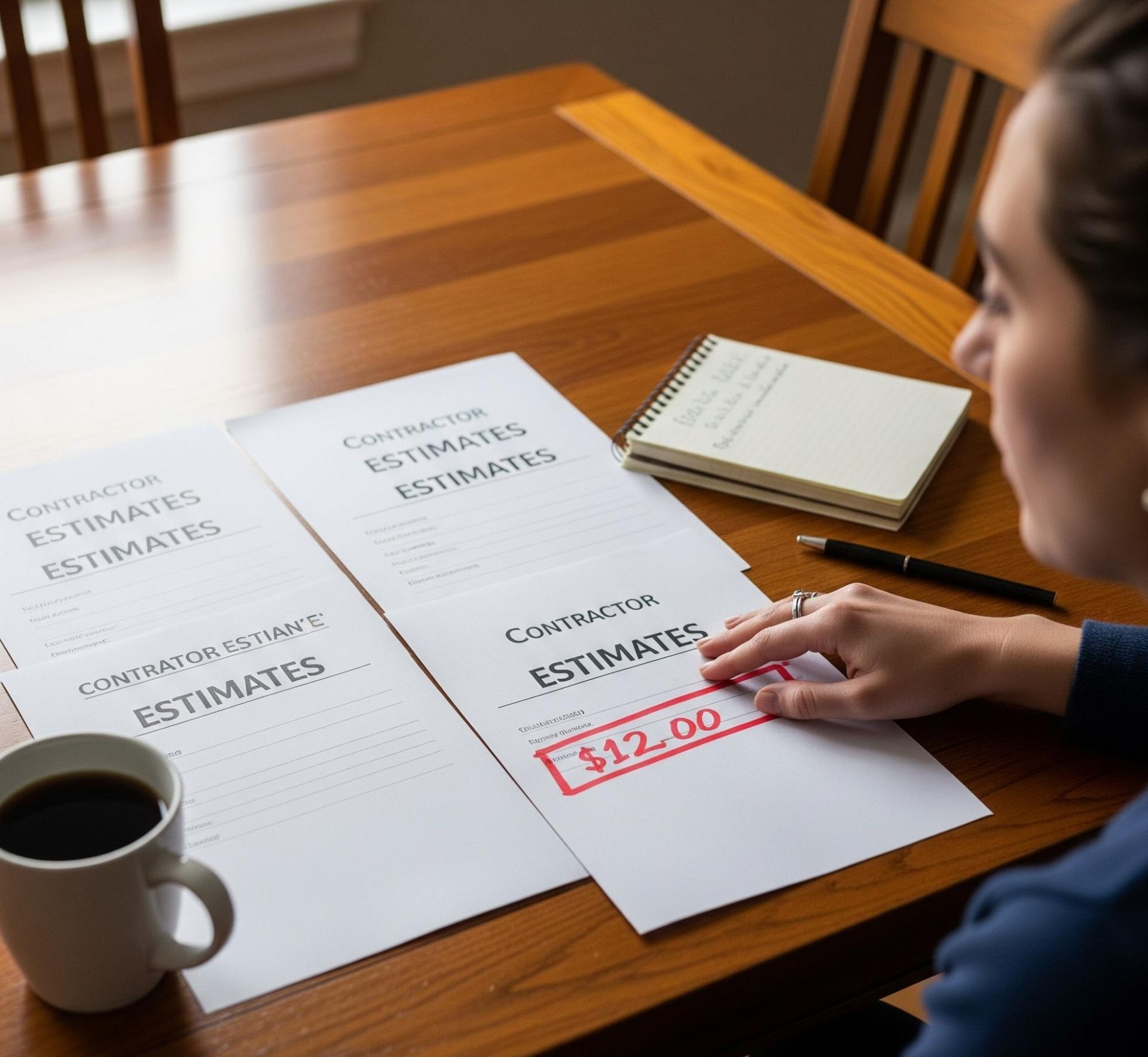

The conference room falls quiet. Two bids sit side by side for a façade restoration in Brooklyn—both scoped correctly, both from reputable teams. One number is noticeably higher because the materials line item isn’t “commodity.” Eyes move from subtotal to scope notes, then back to the total.

This is the moment that matters. For commercial buildings in Brooklyn, the question isn’t merely “Which bid is cheaper?” It’s “Which specification delays the next repair cycle and protects the asset’s value?” What follows is a focused, evidence-driven framework to evaluate sealants, coatings, and flashing on long-term performance and total cost of ownership (TCO)—not just upfront price.

“The most expensive part of a façade restoration is the labor; skimping on material quality is a guarantee you’ll pay that labor cost again sooner than you think.”

Why Material Quality Is the Hidden Driver of Long-Term Façade Performance

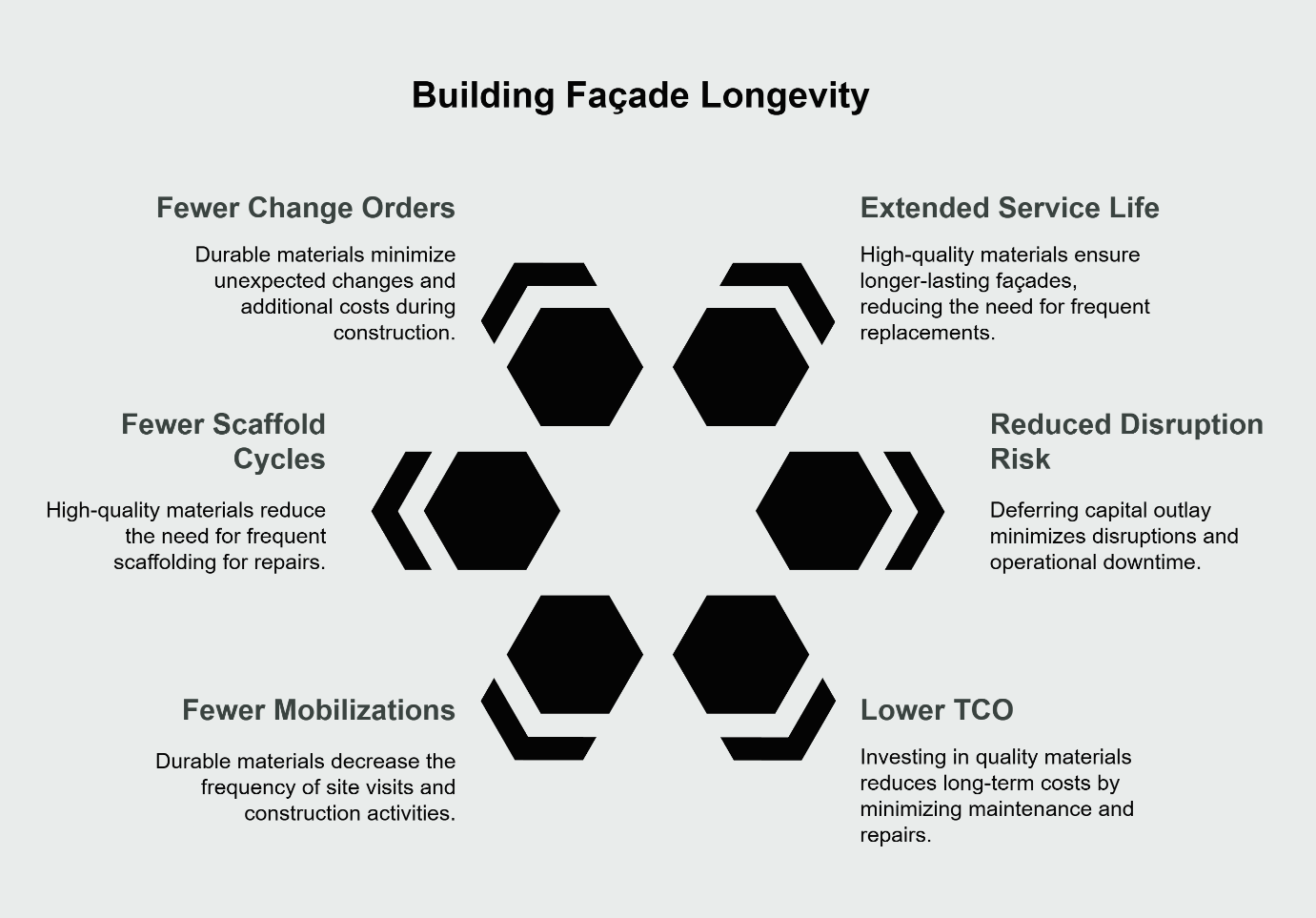

The answer, stated plainly: Quality materials extend service life and push out the next labor event, improving TCO. In portfolio terms, that defers capital outlay and reduces disruption risk. In facility management literature, Total Cost of Ownership is the standard lens for decisions that trade a slightly higher initial cost for fewer, later, and smaller interventions over the asset’s full life.

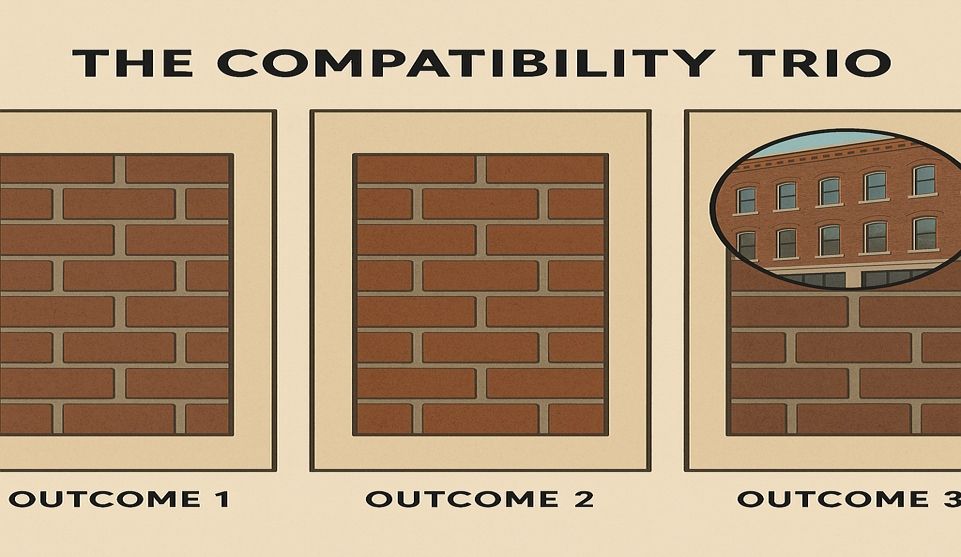

For Brooklyn properties—mid-rise brick, parapet edges, mixed exposure—this means favoring higher-performing sealants, breathable water-repellent coatings, and durable flashing metals where the service conditions warrant. The goal is simple: fewer mobilizations, fewer scaffold cycles, fewer change orders tied to early material failure.

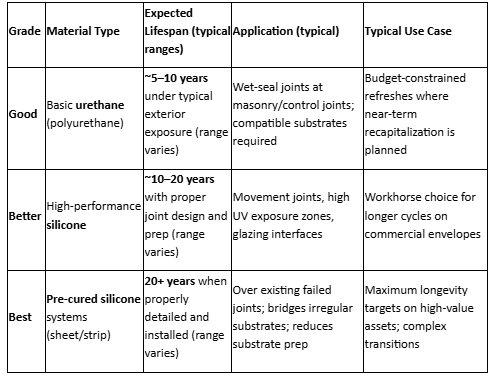

A Comparative Guide to Waterproofing Sealants (Good, Better, Best)

On commercial brick façades in Brooklyn, higher-performance silicone or pre-cured silicone systems typically outlast basic urethanes and better accommodate joint movement, which can reduce premature failure cycles.

Macro view for clarity: A close-up, macro photo comparing bead texture and edge wet-out between low- and high-quality sealant helps stakeholders “see” the difference before they feel it in change orders.

Waterproofing Sealants: A Good, Better, Best Comparison for Long-Term Value

Our POV in one sentence: Because labor drives overall project cost, selecting a sealant grade that maintains adhesion and flexibility longer often delivers the best TCO for Brooklyn commercial assets.

In summary: Choosing silicone or pre-cured silicone where movement, UV, and rain exposure are significant usually pays back through fewer scaffold returns and re-mobilizations.

“Good”: Basic Urethane Sealants

Urethanes bond well to many porous substrates but are more sensitive to UV and often have shorter service lives in exposed conditions. They remain appropriate where budgets or near-term façade phases limit investment—and where detailing limits joint movement.

“Better”: High-Performance Silicone Sealants

Silicones typically retain flexibility and UV resistance longer than urethanes, supporting wider joint movement and longer cycles between replacements. They are common on commercial envelopes with high solar exposure or frequent thermal swing.

“Best”: Pre-Cured Silicone Systems

Pre-cured silicone strips bridge irregular, deteriorated joints with controlled material properties and factory-cured consistency. When detailing is complex—think out-of-plane masonry or uneven substrates—these systems can reduce prep risk and extend service life.

Evaluating Façade Coatings: More Than Just Paint

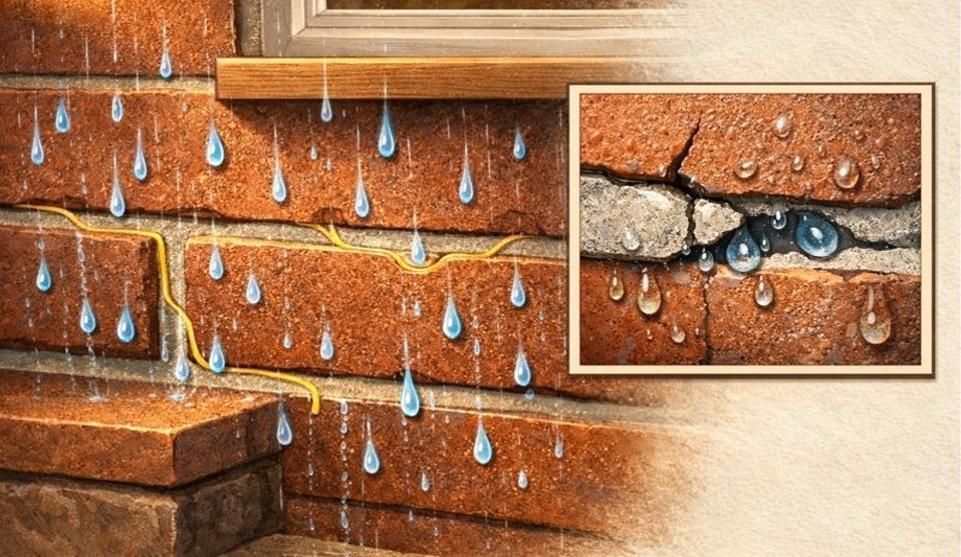

Penetrating silane/siloxane water repellents are typically preferred over film-forming “paint-like” elastomerics for masonry that must shed liquid water yet remain vapor-permeable; the permeability difference helps prevent trapped moisture.

Industry guidance for brick masonry notes that water-repellent coatings are not a cure for underlying defects and that product selection should respect vapor transmission characteristics to avoid trapping moisture within walls—one reason penetrating, breathable treatments are often used for masonry.

Why permeability matters: On many Brooklyn brick façades, inward vapor drive, thermal swings, and intermittent wetting are routine. Systems that block rain but still allow water vapor to escape reduce risk of blistering, spalling, or freeze-thaw distress behind a coating.

Key terms to track in submittals: permeability (often measured via standardized tests), water absorption reduction, substrate compatibility, and application temperature/humidity windows.

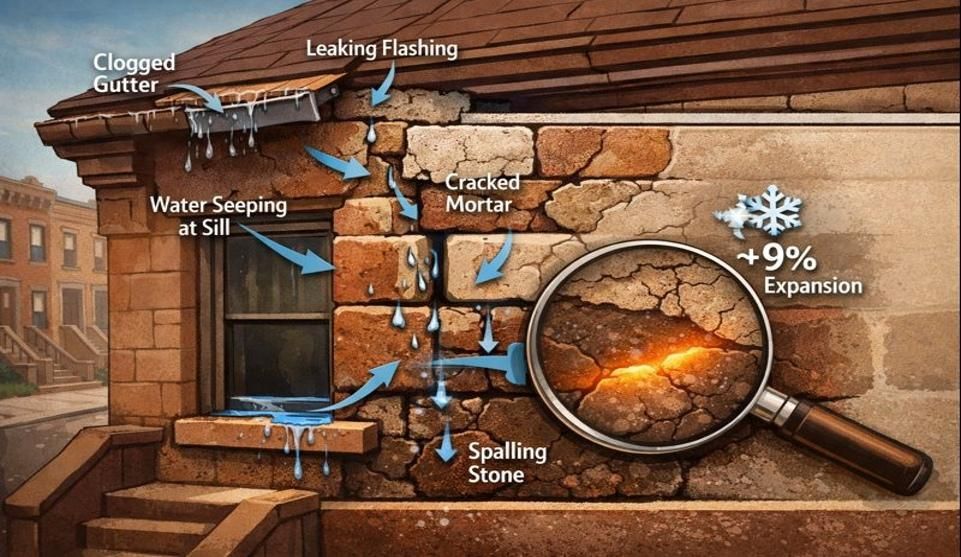

The Critical Role of Flashing in Water Diversion

Answer first: Flashing is the frontline defense against water entry at transitions—sills, heads, parapets, shelf angles—and material selection has outsized consequences. Stainless steel and copper generally offer greater corrosion resistance and durability than plain galvanized steel in demanding exposures, reducing the likelihood of early failures at critical joints.

Federal technical guidance treats flashing as an integral water-management component and emphasizes that failures at these transitions are a common source of infiltration requiring experienced remediation.

Material comparison (illustrative):

- Galvanized steel: Economical; coating can degrade and corrode faster in aggressive urban exposures.

- Stainless steel: Strong corrosion resistance; suited to long-cycle details and exposed edges.

- Copper: Durable and formable; often chosen where longevity and complex forming are needed.

Detailing note: Laps, end-dams, weeps, and continuity across planes matter as much as metal choice. Poor terminations can negate a premium alloy.

What If…? Planning for the High Cost of Premature Material Failure

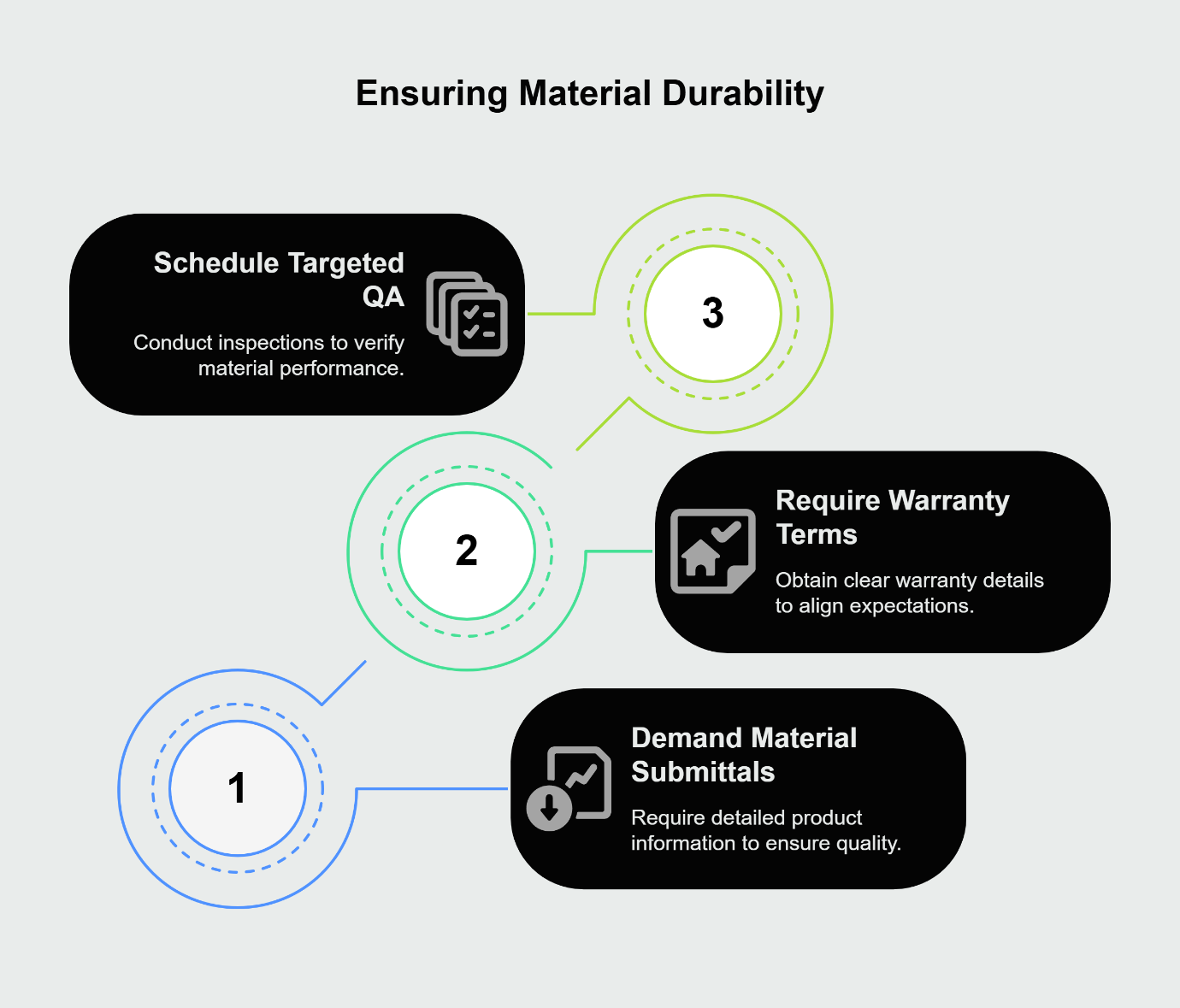

The concern is valid: early sealant or flashing failure means another mobilization, more access costs, more disruption. To stay in control, enforce a concise, defensible plan:

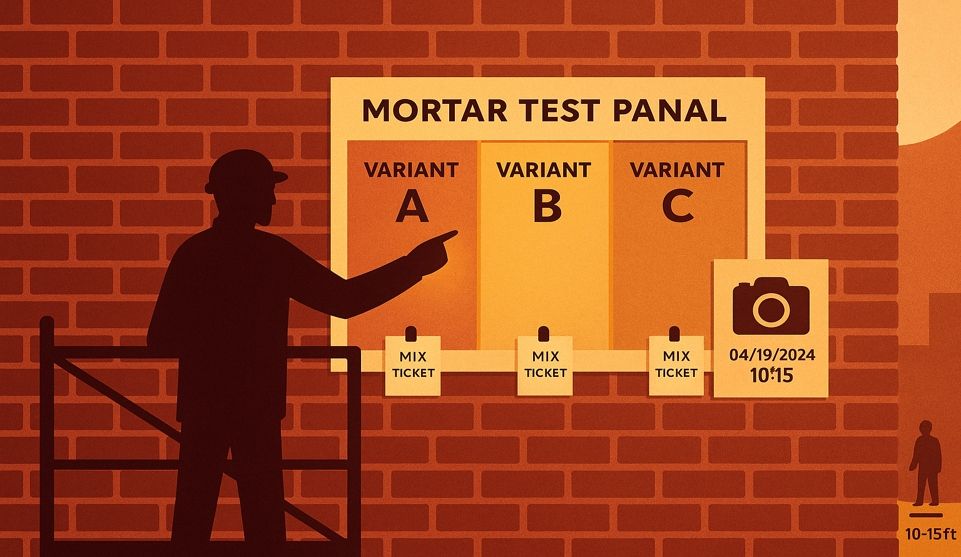

1. Demand full material submittals, not just brand names. Require product type, performance properties (e.g., permeability, movement capability), and installation procedures clearly stated for each location.

2. Require manufacturer warranty terms in the bid. Ask for warranty duration and conditions for all proposed sealants, coatings, and flashing; this aligns expectations with realistic maintenance cycles.

3. Schedule targeted QA. Include field adhesion tests for sealants at mockups and first-work areas, and inspect flashing terminations and end-dams before concealment.

Most teams miss step two. Don’t. It’s where lifecycle reality meets procurement language.

From Comparing Bids to Protecting Your Asset

Bids are numbers; specifications tell the story. For Brooklyn commercial buildings, investing in higher-performing sealants, breathable repellents, and durable flashing metals is not an upsell—it’s asset protection through fewer repair cycles and better TCO.

Seen through a broader lens, this decision-making discipline is exactly what future asset managers practice at portfolio scale: calibrating service life, capital timing, and risk—so today’s façade line item becomes tomorrow’s predictable plan rather than an emergency mobilization.

See What Strong Material Choices Look Like

Explore exemplar outcomes and specification approaches in action: Project Gallery. If a quick scope check is needed first, request a FREE Photo Estimate to align on priorities and timeframes.

This article provides general information about facade material selection for educational purposes. Individual circumstances vary significantly based on factors like building age, material of construction, local climate, and budget. For personalized guidance tailored to your building's long-term durability and asset protection, it is recommended to consult with a qualified professional.

Related Resources on City Suburb

- Coordinating scope with masonry contractors in Brooklyn, NY for envelope-wide execution.

- When joint integrity and water shedding intersect with masonry joints: brick pointing in Brooklyn, NY.

- Edge conditions matter: parapet wall reconstruction in Brooklyn.

- Methodology deep-dive for historic substrates: Why the Right Mortar Mix is Everything for Historic Brooklyn Brick.

- Budget risk cautionary read: Why a “Patch Job” Can Be the Most Expensive Repair of All.

Technical Notes & Evidence

- TCO framing for facility decisions is a standard practice in facilities management.

- Brick masonry coating guidance emphasizes breathable, compatible treatments and cautions against using repellents as substitutes for repairs.

- Flashing is recognized as a critical water-management element requiring experienced detailing and repair.

This guide is intended as a comprehensive starting point. For decisions specific to your unique situation, we always recommend consulting a qualified professional.

Our expert team uses AI tools to help organize and structure our initial drafts. Every piece is then extensively rewritten, fact-checked, and enriched with first-hand insights and experiences by expert humans on our Insights Team to ensure accuracy and clarity.

About the City Suburb Insights Team

'The City Suburb Insights Team is our dedicated engine for synthesizing complex topics into clear, helpful guides. While our content is thoroughly reviewed for clarity and accuracy, it is for informational purposes and should not replace professional advice.'