Lime Mortar vs. Cement: Why the Right Material Matters for Historic Brick

📌 Key Takeaways

The wrong mortar choice on historic brick doesn't just look bad—it traps moisture, cracks the brick, and turns a simple repointing job into expensive brick replacement.

- Softness Is Strategy, Not Weakness: Historic masonry survives when mortar sacrifices itself before the brick does, making lime's flexibility the smarter long-term investment over cement's rigid strength.

- Breathability Prevents the Real Damage: Lime mortar acts like Gore-Tex for walls—shedding rain while releasing trapped vapor—so freeze-thaw cycles crack the replaceable joint instead of popping irreplaceable brick faces.

- "Stronger" Mortar Is a Trap for Old Brick: Portland cement exceeds the compressive strength of pre-war brick, reversing the protective relationship and forcing the brick to absorb all seasonal movement and moisture stress.

- Test Panels Prevent Expensive Regret: Mortar color shifts dramatically as it cures and weathers, making small trial areas under real daylight the only reliable way to confirm a match before committing to full-scale repointing.

- 30 to 50 Years Beats 10 to 15: Properly executed lime repointing on compatible historic brick typically lasts three to five times longer than cement repairs, with the added benefit of self-healing micro-cracks through natural carbonation.

Prepared with period-correct materials = preserved architectural character and lower lifetime repair costs.

Brooklyn, Bronx, and Long Island homeowners with pre-war brick will gain clarity here, preparing them for the detailed material comparisons and local contractor guidance that follows.

The rain started during dinner. By midnight, Sarah noticed a hairline crack tracing the mortar line near her brownstone's living room window. Water had darkened the brick below the sill. She'd paid a contractor to "fix" these joints just two years ago with what he'd called "strong mortar." Now the cracks were back—wider than before.

The problem wasn't the work. It was the material. Portland cement seems logical for repairs: it's hard, durable, readily available. But old brick doesn't need strength. It needs compatibility.

The Short Answer

Historic brick in Brooklyn, the Bronx, and Long Island was handmade before modern firing techniques existed. These softer units expand and contract with seasonal temperature changes, absorb moisture during rain, and release it when conditions dry. Lime mortar moves with this natural cycle and allows walls to breathe. Portland cement doesn't. Its rigid, moisture-tight structure traps water inside masonry, creating pressure that forces the brick—not the mortar—to fail through spalling and cracking.

National Park Service guidance explicitly recommends replacement mortars that are softer and more vapor-permeable than the original masonry units. This isn't aesthetic preference. It's structural necessity.

"The mortar must always be softer than the brick."

This principle has guided masonry preservation for generations. When the mortar serves as the sacrificial element, it deteriorates gradually over decades while protecting the more valuable brick units. When cement creates an unyielding bond, the brick becomes the weak link.

Myth to retire: "Stronger mortar lasts longer"

For new concrete block, stronger mortar can offer advantages. For century-old soft brick, it creates the opposite effect. Very strong, rigid cement mortar doesn't protect the wall—it makes the brick the weakest part of the system. Over time, brick faces chip, crack, and spall while joints stay rigid. The mortar joint should be the sacrificial element and the brick the protected heirloom.

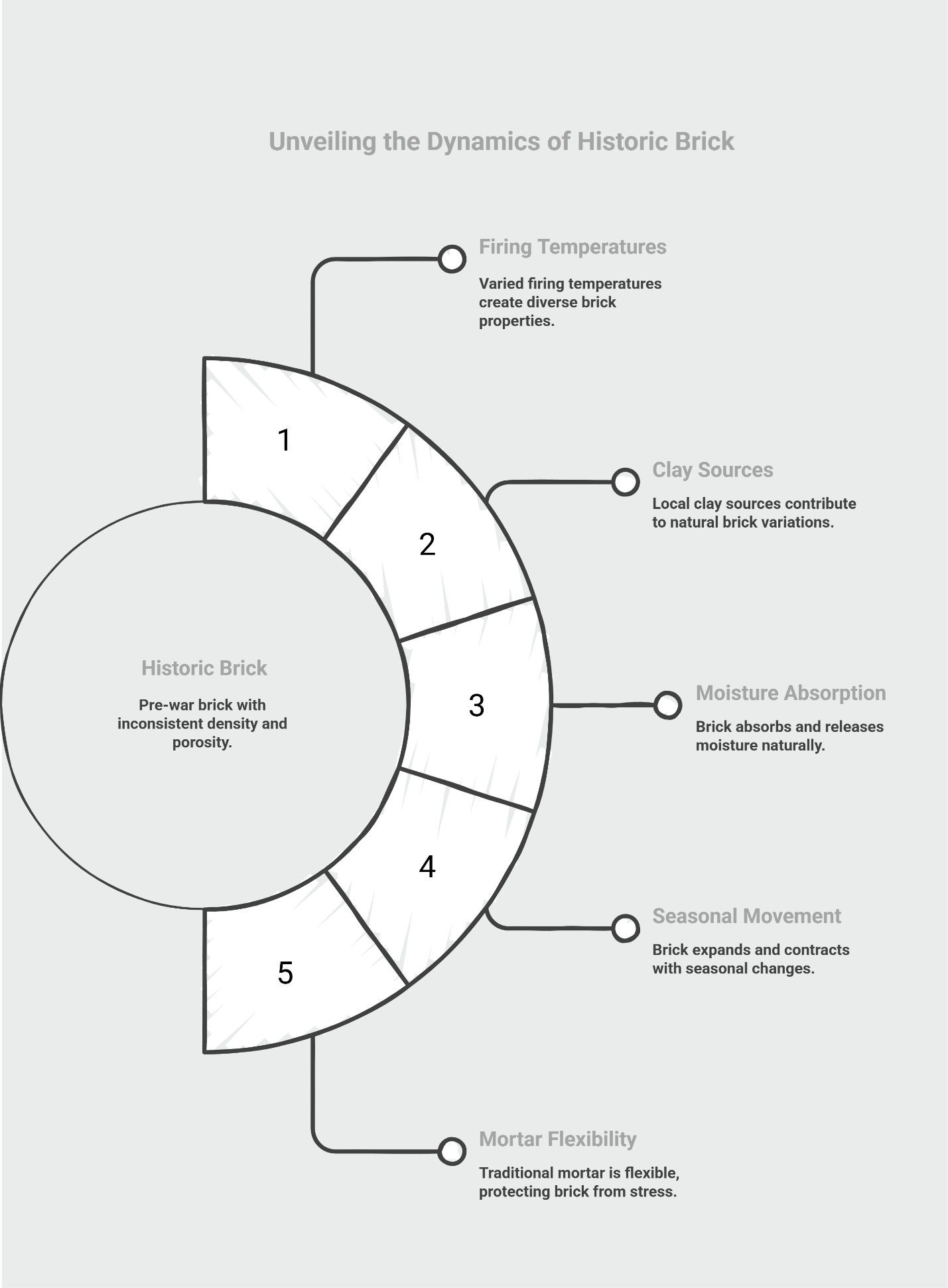

What's Different About Historic Brick?

Pre-war brick differs fundamentally from modern units. Firing temperatures varied across each kiln load, creating units with inconsistent density and porosity. The clay itself came from local sources with natural variations. These handmade bricks have wider pore structures that absorb and release moisture as part of their normal behavior.

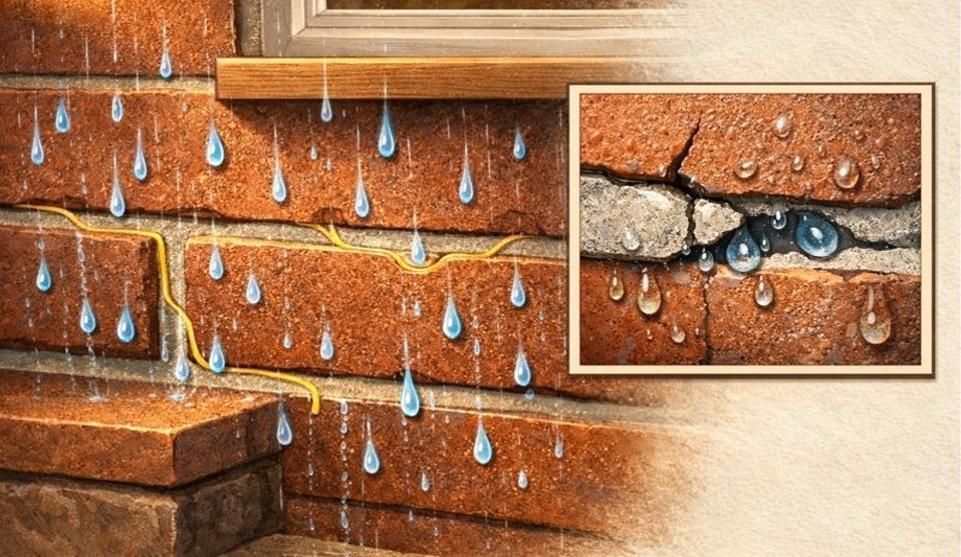

This breathing capacity matters. During New York's wet springs and humid summers, brick absorbs moisture from rain and atmospheric humidity. In drier conditions, that moisture evaporates back through the brick face and through the mortar joints. The system works as long as nothing blocks the path.

Seasonal movement compounds the challenge. Brick expands slightly when wet and contracts when dry. It expands with heat and contracts with cold. These small movements occur constantly throughout the year. Mortar joints must accommodate this motion without creating stress concentrations that crack the masonry.

The traditional approach recognized these realities. Original lime-based mortars were deliberately formulated to be softer and more flexible than the brick units they joined. When problems developed, the mortar—the less expensive, more easily replaced component—took the damage. The brick remained sound.

Modern cement reverses this relationship. Its compressive strength often exceeds that of historic brick. Its rigidity prevents the accommodating movement that soft mortar allows. When stress develops from seasonal changes or settling, the cement remains intact while the brick cracks. Repairs become dramatically more expensive because brick replacement requires far more skill and material cost than repointing.

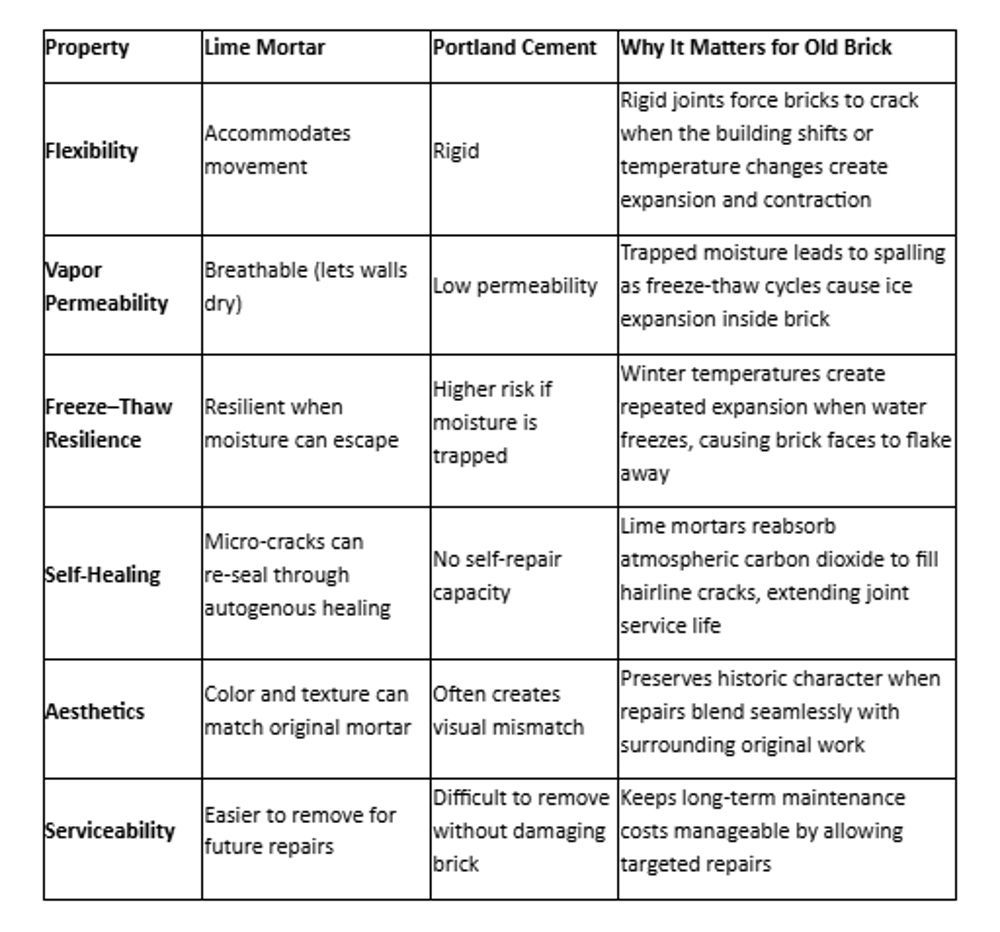

Lime vs. Cement—A Side-by-Side Comparison

Understanding how these materials differ explains why the wrong choice creates recurring problems:

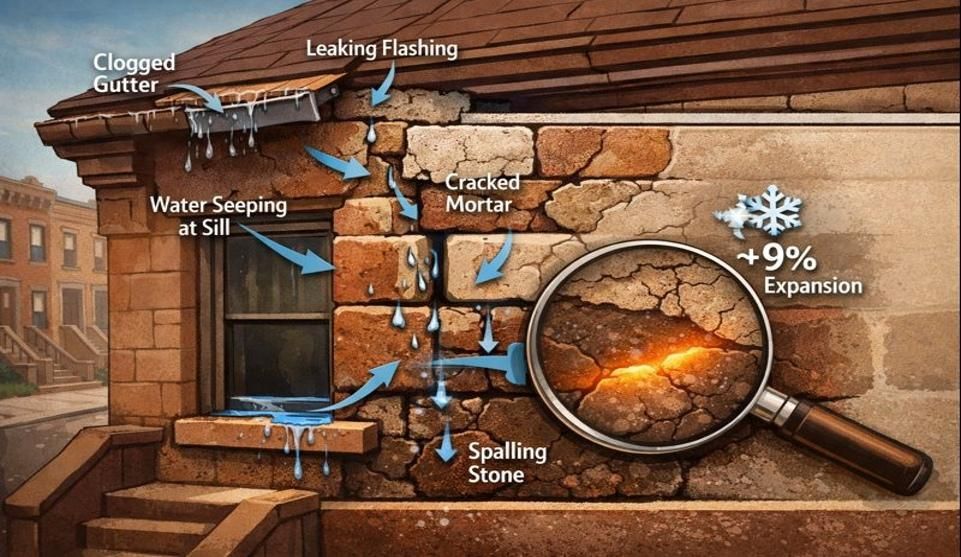

The breathability difference deserves particular attention. Research from preservation organizations including the National Park Service has documented how vapor permeability affects masonry performance in freeze-thaw conditions. When moisture can migrate through mortar joints, it escapes before temperatures drop below freezing. When cement traps that moisture, freezing water expands with enough force to pop brick faces off in thin layers—a failure mode called spalling.

The self-healing property represents a less widely understood advantage. Current research on advanced lime mortars confirms that well-designed lime or Natural Hydraulic Lime (NHL) mixes provide good durability, adequate strength, and beneficial vapor permeability when used correctly in historic masonry. Lime mortars undergo a slow carbonation process where atmospheric carbon dioxide reacts with calcium hydroxide to form calcium carbonate. This process continues for years after installation and can seal micro-cracks that develop from normal building movement, effectively extending joint life without intervention.

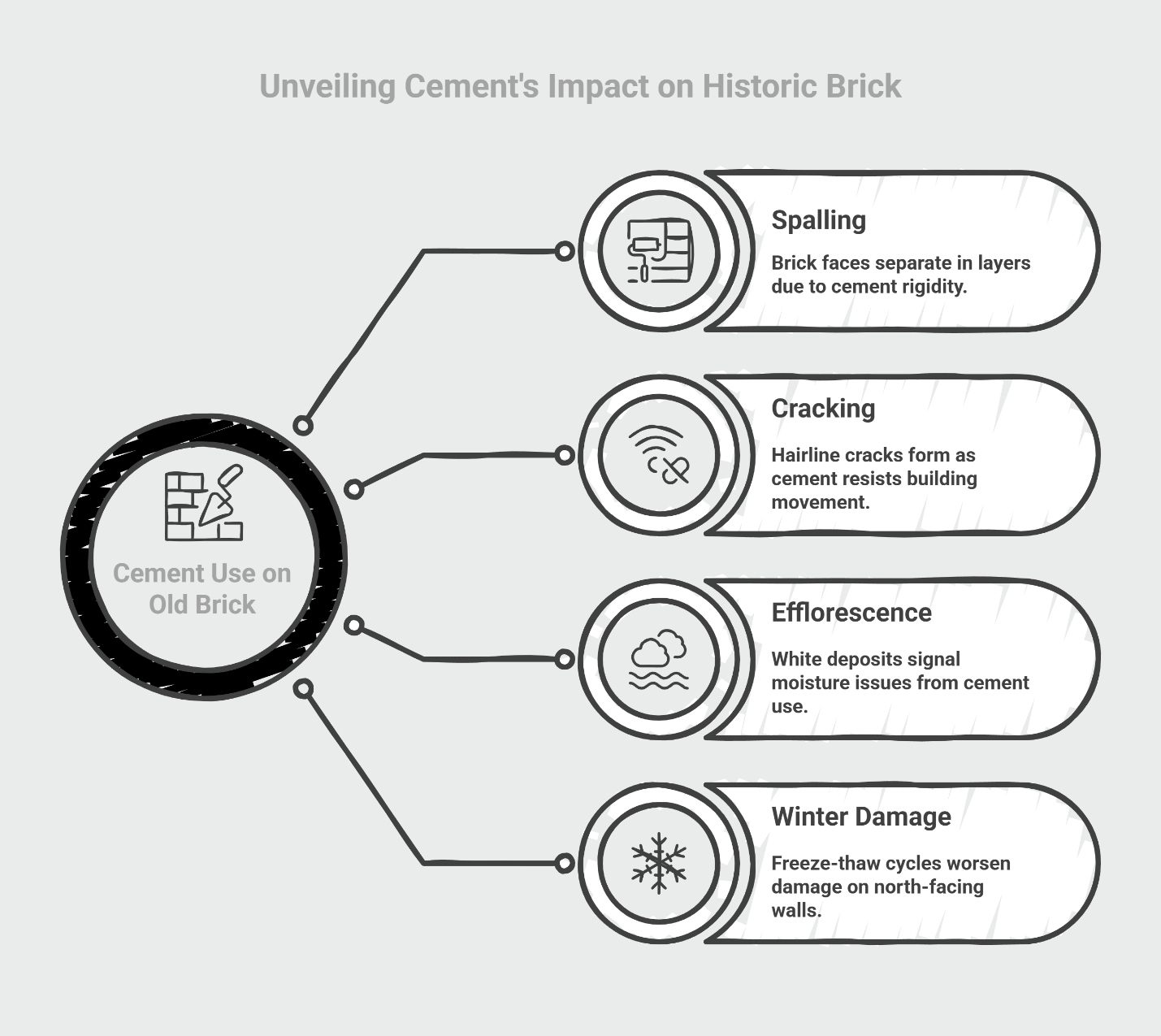

The Damage We See When Cement Is Used on Old Brick

Certain failure patterns appear consistently when Portland cement repairs soft historic brick. Spalling typically begins within three to five years of cement repointing, appearing first on the most exposed facades. The brick face separates in thin layers, often following the horizontal coursing. Water enters through failed joints, saturates the brick, then expands on freezing. Because the cement prevents moisture from escaping through the joints, pressure builds inside the brick until the face fails.

Hairline crack networks develop as cement's rigidity resists normal building movement. These cracks often follow step patterns along mortar joints, then extend through brick faces when stress concentrations exceed the brick's tensile strength. The cracks provide new pathways for water infiltration, accelerating deterioration.

Efflorescence—white crystalline deposits on brick surfaces—signals moisture moving through the masonry. When cement blocks the normal path through mortar joints, water finds alternative routes through the brick itself, dissolving salts along the way. These salts deposit on the surface as water evaporates, creating both aesthetic problems and evidence of ongoing moisture issues that will worsen with continued freeze-thaw cycling.

Winter presents the harshest test. When nor'easters and cold fronts strike, buildings in Brooklyn Heights, Park Slope, and similar historic neighborhoods show characteristic damage patterns on north-facing walls where freeze-thaw cycles occur most frequently. Brick faces flake away gradually, exposing the softer interior material to further deterioration. Once spalling begins, it accelerates because each failure exposes more surface area to moisture penetration.

Choosing the Right Lime Mix (Without Going Ultra-Nerd)

The phrase "lime mortar" encompasses several formulations, each suited to different applications. The goal is matching the characteristics of original mortar in both physical properties and appearance. This "like-for-like" principle ensures that repairs perform similarly to the original construction.

Natural Hydraulic Lime (NHL) has become the standard for most historic brick repointing. Unlike pure lime putty, NHL sets through both carbonation and a hydraulic reaction that occurs in the presence of water. This gives it better early strength while maintaining the flexibility and breathability that historic brick requires. NHL comes in different grades based on compressive strength, with NHL 3.5 suitable for most residential masonry applications.

The relationship between NHL and Portland cement requires clarification. Some contractors add cement to lime mortars claiming it provides necessary strength. This practice defeats the primary advantages of using lime in the first place. The cement component creates the same rigidity and impermeability issues that caused problems with pure cement repointing. For soft historic brick, strength is not the goal—compatibility is.

Mortar matching involves more than just selecting the right binder. The sand used in the mix affects both performance and appearance. Sand particle size, shape, and color all influence how the finished mortar looks and behaves. Original mortars often used locally sourced sand with specific characteristics that contribute to their distinctive appearance in different neighborhoods.

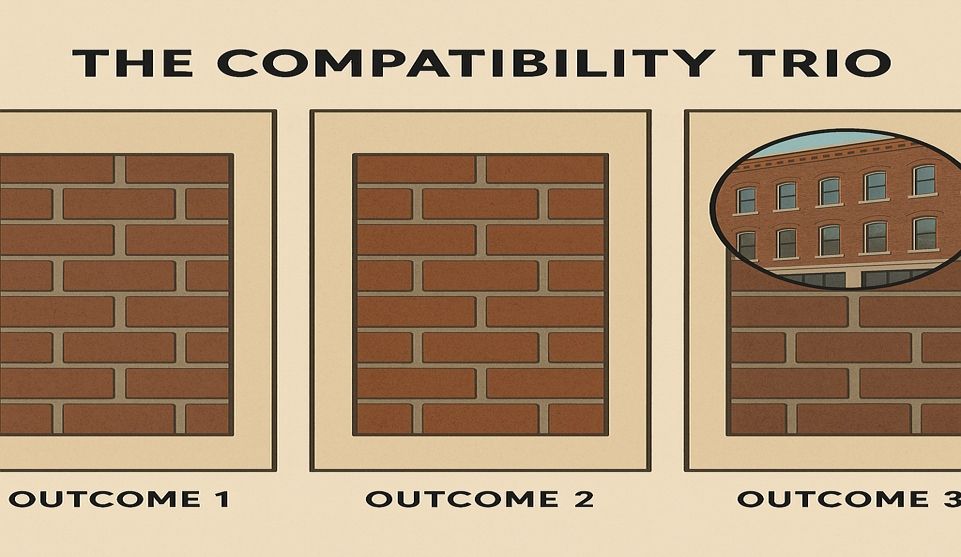

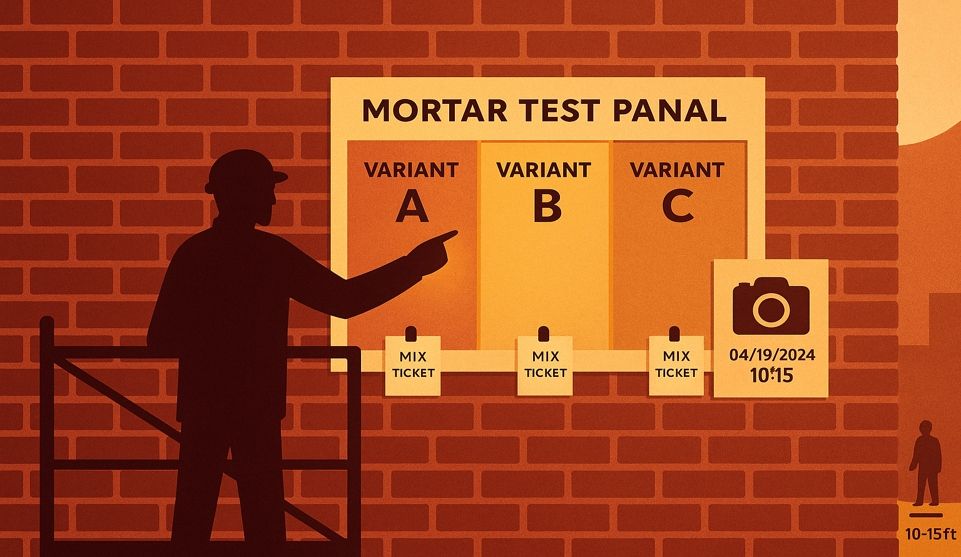

This complexity explains why the right mortar mix is everything for historic Brooklyn brick. Small sample areas allow evaluation of the proposed mortar mix under actual conditions. Color shifts as mortar cures and weathers, often looking quite different after several weeks than it did when first applied. Reviewing test panels at various distances and lighting conditions ensures the final result will blend appropriately with surrounding original work.

The NYC mortar matching & test panels process addresses these concerns systematically, providing homeowners with confidence that repairs will be both structurally sound and aesthetically appropriate.

What This Means for Your NYC Facade

Proper lime-based repointing transforms more than just appearance. The building envelope becomes genuinely watertight rather than trapping moisture inside wall assemblies. Water sheds off the surface during rain, and any moisture that penetrates dries through the joints between storms. This cycle prevents the accumulation that leads to freeze-thaw damage.

Service life extends dramatically. While cement repointing typically requires intervention again within ten to fifteen years, properly executed lime repointing typically lasts 30 to 50 years under good conditions before requiring attention. The investment in correct materials and skilled application pays returns over decades.

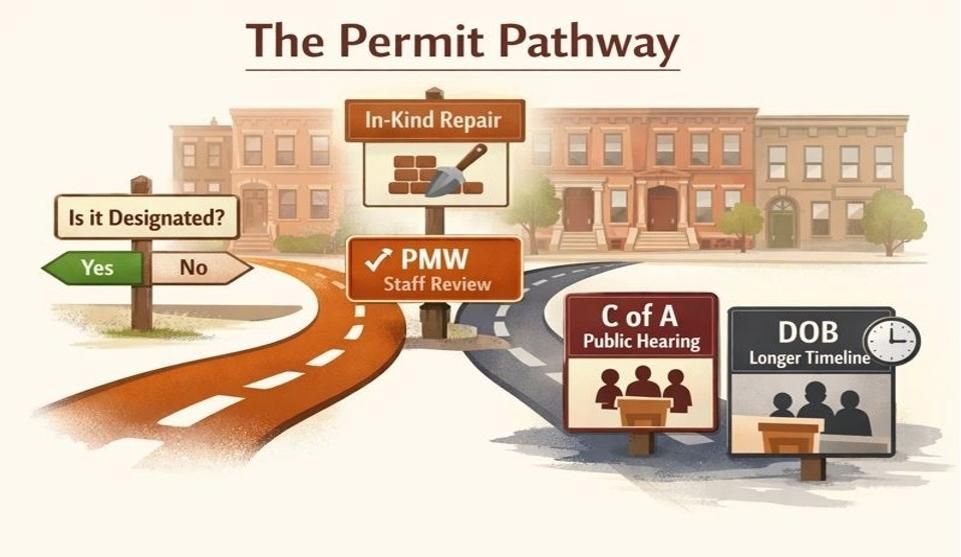

Historic character remains intact. Buildings that define Brooklyn's architectural landscape maintain their authentic appearance when repairs respect original construction methods. For properties in landmark districts, this authenticity isn't just aesthetic preference—it's often a regulatory requirement.

The challenge lies in finding contractors who understand these principles and execute them correctly. What 'compatible mortar' really means extends beyond simply using lime instead of cement. It requires knowledge of historic construction practices, material science, and the specific challenges that Brooklyn, the Bronx, and Long Island climates present.

Homeowners benefit from on-site assessment that examines existing conditions and develops appropriate solutions. Some facades require only targeted repairs where damage has occurred. Others need comprehensive repointing after decades of weathering have compromised the original mortar. Still others may have a patchwork of previous repairs in incompatible materials that need systematic replacement.

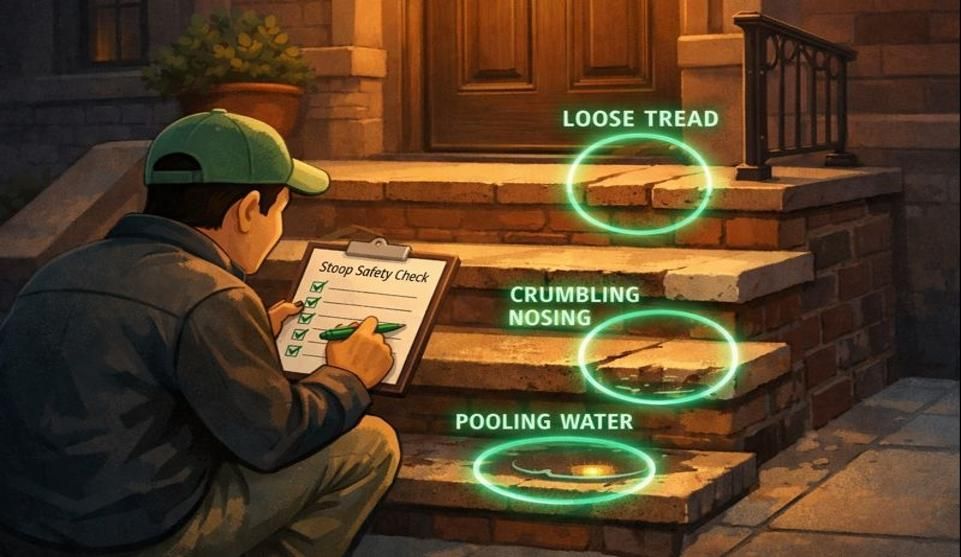

The time to address these issues comes before damage becomes severe. Signs your home needs professional repointing appear years before structural problems develop. Early intervention allows selective repairs that preserve more original fabric and cost substantially less than waiting for comprehensive failures.

Ready to protect your home's masonry with period-correct materials? City Suburb, Inc. brings two decades of experience to Brick Pointing services throughout Brooklyn, the Bronx, and Long Island. Our approach emphasizes compatible lime-based mortars, careful material matching, and proven installation techniques that preserve historic character while delivering lasting performance. Learn more about what to expect during brick repointing in NYC or explore our work in the gallery.

Schedule a Free On-Site Inspection by contacting us or call (718) 849-8999 to discuss your specific needs with our team.

Service Area: Brooklyn • Bronx • Long Island

Expert Corner: Autogenous Healing

Lime mortars possess a remarkable property that cement lacks: the ability to seal minor cracks through autogenous healing. Laboratory and field studies show that in lime and lime-NHL mortars, fine cracks can gradually fill as dissolved lime and other minerals re-precipitate within the crack, especially in the presence of moisture and carbon dioxide. As lime mortar slowly reacts with atmospheric carbon dioxide over months and years, it forms calcium carbonate crystals. When hairline cracks develop from normal building movement, this carbonation process continues within the crack, gradually filling the gap and restoring the joint's integrity. This self-repair mechanism extends service life and explains why properly installed lime repointing outlasts cement alternatives.

Frequently Asked Questions

Can I add a little cement "for strength"?

Adding cement to lime mortar undermines the flexibility and breathability that make lime appropriate for historic brick. Even a modest cement addition can shift a mortar from flexible and breathable to overly rigid or dense for older units. The National Park Service and many state preservation offices caution against cement-rich mixes where original mortars were lime-based, precisely because they can drive damage into the brick. The cement component creates rigid zones that trap moisture and resist movement, reproducing the exact problems that lime-only mortars avoid. For soft historic brick, the mortar should remain softer than the units it joins—cement additions work against this principle.

Is NHL okay for my brownstone or brick house?

Natural Hydraulic Lime (NHL) has become the standard for most historic masonry repointing. It provides adequate early strength through its hydraulic set while maintaining long-term flexibility and breathability through continued carbonation. Research from the National Center for Preservation Technology confirms NHL's suitability for many historic brick and stone structures when carefully specified. Whether NHL is appropriate for your specific facade depends on original mortar characteristics, brick hardness and condition, and exposure conditions. NHL 3.5 grade suits most residential applications, though specific situations may require different formulations. A site inspection and test panels are the safest way to confirm suitability.

How long will proper repointing last?

Lime-based repointing executed with compatible materials and proper technique typically provides 30 to 50 years of service under good conditions before requiring intervention. This dramatically exceeds the ten-to-fifteen-year lifespan common with cement repointing of historic brick. Durability depends on several factors including mortar formulation, installation quality, facade exposure, and ongoing building maintenance. Regular inspections—especially after major storms—help catch localized issues early.

Can repointing happen in winter?

Lime mortar requires temperatures above freezing during application and initial curing. Winter repointing becomes feasible with heated enclosures that maintain appropriate conditions at the work area. These temporary structures protect freshly installed mortar from freezing while allowing proper carbonation. Projects scheduled for winter require this additional protection, which affects both timeline and cost compared to work during moderate weather.

How do you ensure color and texture match?

Material matching begins with analysis of existing mortar to understand its composition, sand characteristics, and proportions. Test panels created with various formulations allow evaluation under actual conditions as mortars cure and weather. Reviewing these panels at different distances and times of day reveals how closely proposed mixes match surrounding original work. Only after approval of test panels does full-scale repointing proceed, ensuring repairs blend seamlessly with the building's historic fabric. The Brooklyn Heights & Park Slope assessment guide provides more details on this process. Visit our areas we serve page to see if your neighborhood is covered.

Our Editorial Process

Our expert team uses AI tools to help organize and structure our initial drafts. Every piece is then extensively rewritten, fact-checked, and enriched with first-hand insights and experiences by expert humans on our Insights Team to ensure accuracy and clarity.

About the City Suburb Insights Team

The City Suburb Insights Team is our dedicated engine for synthesizing complex topics into clear, helpful guides. While our content is thoroughly reviewed for clarity and accuracy, it is for informational purposes and should not replace professional advice.