Historic Brick Pointing in Brooklyn: What ‘Compatible Mortar’ Really Means for Your Home

📌 Key Takeaways:

Compatible mortar isn't about matching color—it's about matching strength, permeability, texture, and joint profile to protect your brick rather than damage it.

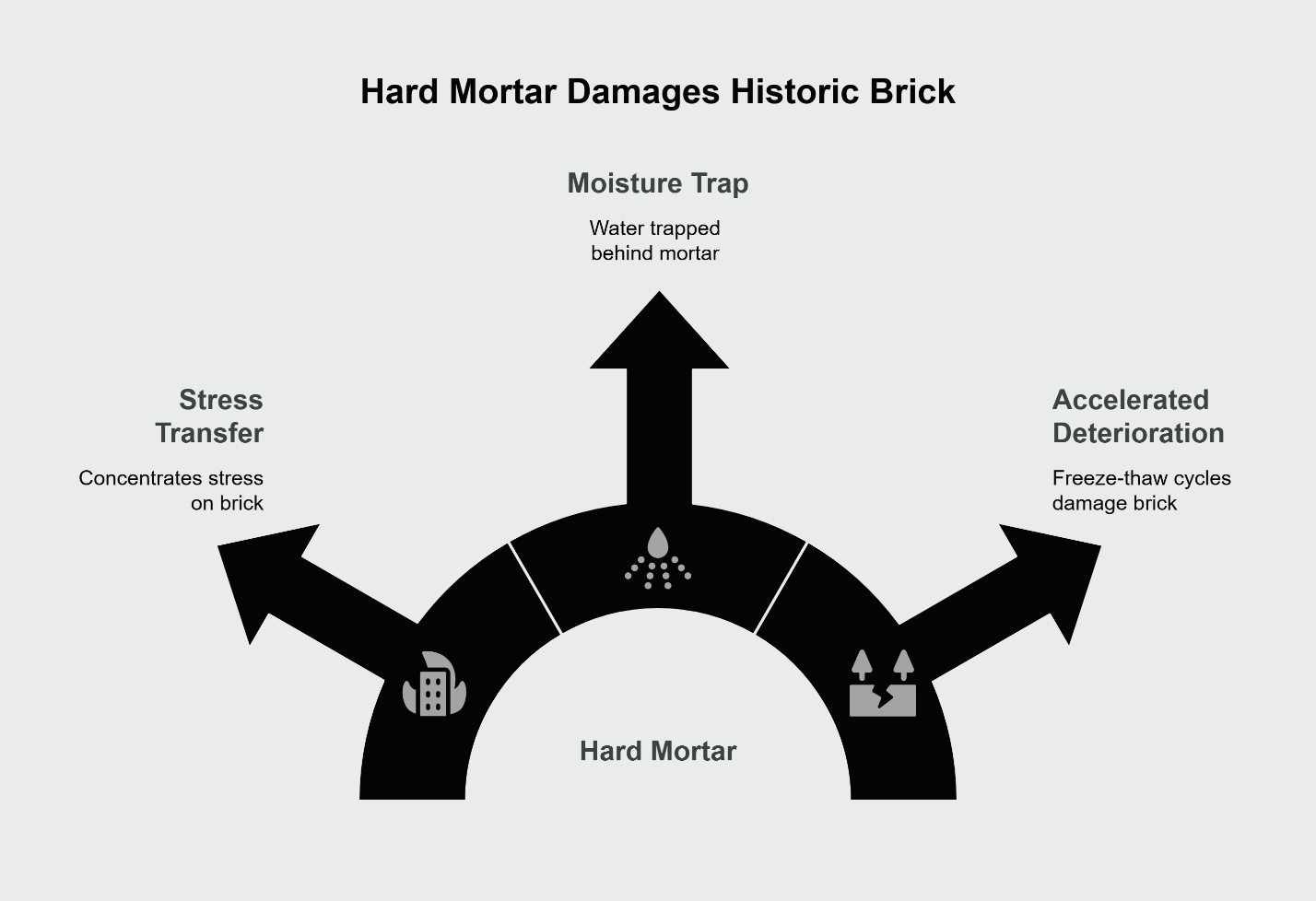

Hard Modern Mortars Backfire: Over-strength Portland cement mixes trap moisture, transfer stress to softer historic brick, and accelerate spalling and efflorescence instead of preventing it.

Test Panels Prevent Costly Mistakes: Small trial sections reviewed at multiple distances and in varied light conditions confirm texture, color, and tooling before committing to full-scale work.

Permeability Protects Structure: Lime-based mortars allow moisture vapor to escape safely through joints, preventing freeze-thaw damage and salt migration that dense mixes cause by trapping water inside walls.

Joint Profile Matters as Much as Color: Weather-struck, flush, or concave tooling affects both appearance and water-shedding performance—matching the original profile honors the building's character and ensures proper drainage.

Document Everything for Consistency: Recording approved mix proportions, joint types, and installation conditions creates a baseline that maintains quality across different work phases and future maintenance.

Prepared with compatible materials and proper testing = decades of protection for Brooklyn's historic façades.

For Brooklyn homeowners managing landmark properties or pre-war townhouses seeking preservation-compliant brick pointing solutions that protect both structure and character.

Quick Answer: Compatible mortar matches your original brick's strength, permeability, texture, color, and joint profile—sealing out water without stressing the masonry. It's the difference between a repair that protects your façade for decades and one that accelerates damage.

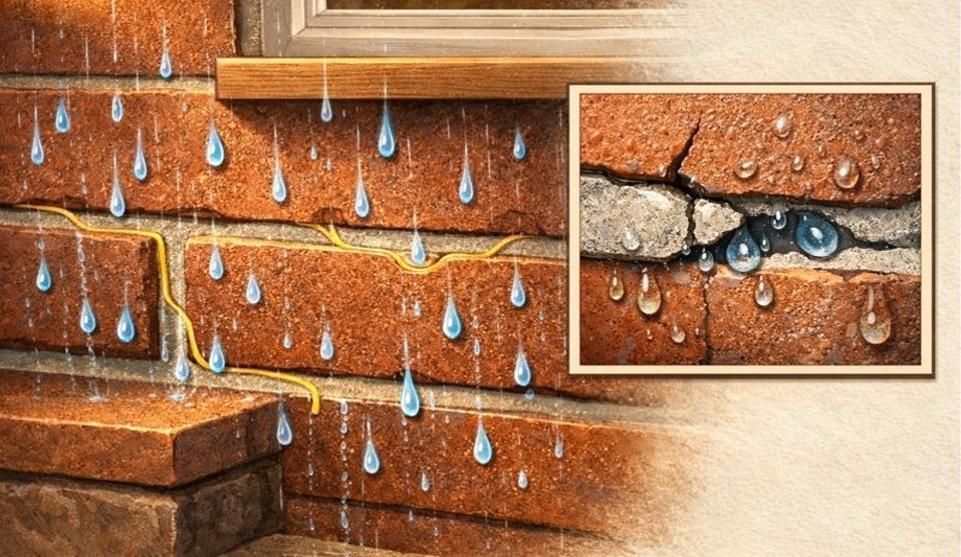

You notice the mortar joints on your Park Slope or Carroll Gardens townhouse are crumbling. Water finds its way behind the brick during every heavy rain. The instinct is to patch those gaps quickly, seal everything tight, and move on.

That instinct can backfire. Hard modern mortars may seem like the stronger choice, but they often trap moisture inside the wall and stress the softer historic brick around them. The result: spalling, efflorescence, and costlier repairs down the road. For pre-war and landmarked homes across Brooklyn—and throughout the Bronx, Manhattan, Queens, and Long Island—the right approach starts with understanding what "compatible" really means.

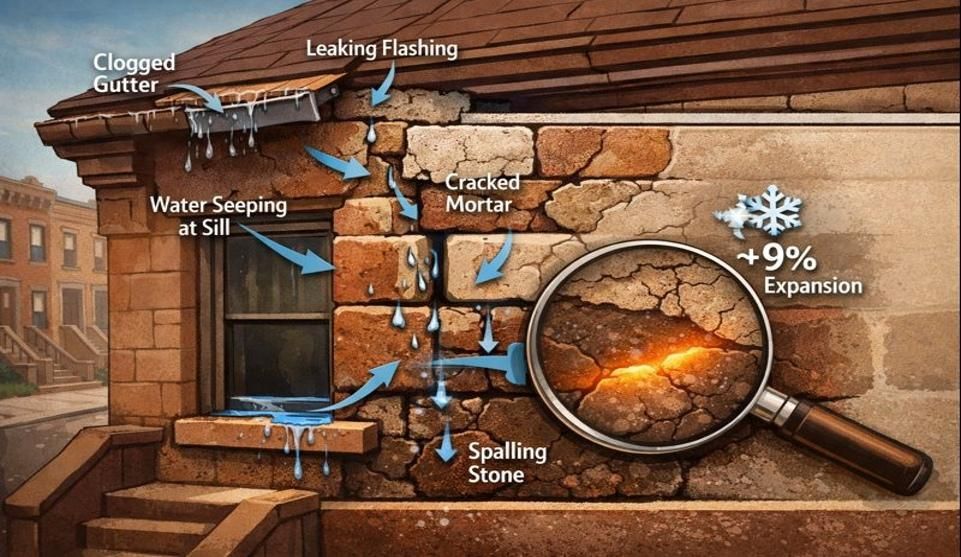

Why Compatibility Matters (and Over-Hard Mortars Fail)

Historic brick was fired at lower temperatures than modern units, making it softer and more porous. The original lime-based mortars were intentionally weaker than the brick, acting as a sacrificial element that could weather and be renewed without damaging the masonry itself.

When an over-hard Portland cement mix is forced into those joints, it reverses the hierarchy. The mortar becomes stronger than the brick. As the wall expands and contracts with temperature swings, stress concentrates at the brick face rather than at the joint. Water vapor that once escaped through permeable mortar gets trapped behind a dense barrier, where freeze-thaw cycles and salt crystallization do their damage from within.

This isn't speculation. Federal preservation guidelines and NYC Landmarks Preservation Commission standards emphasize mortar compatibility precisely because mismatched repairs have damaged thousands of historic façades. The National Park Service's Preservation Brief 2 documents how incompatible repointing accelerates deterioration rather than preventing it.

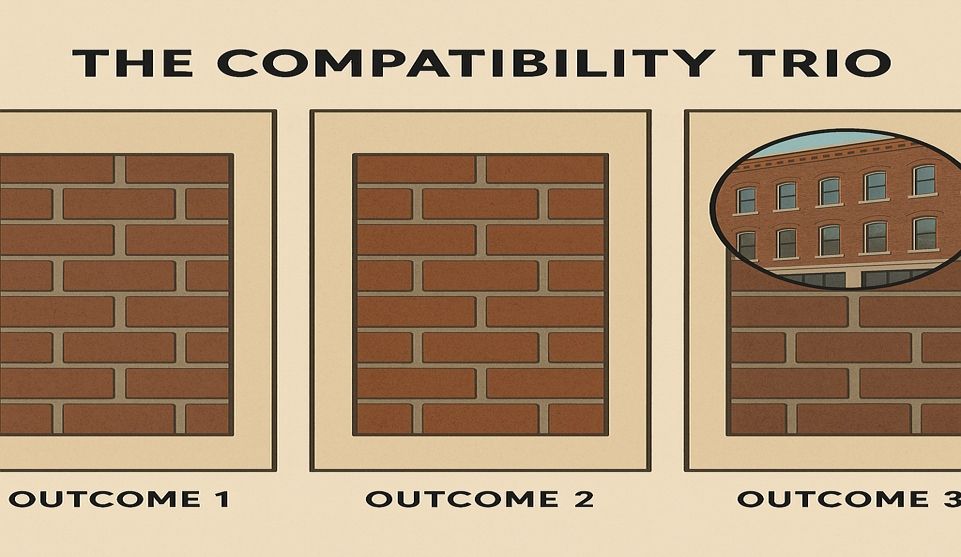

The Compatibility Triangle: A Simple Mortar-First Litmus

Choosing the right mix isn't about picking a color from a chart. Four interconnected factors determine whether a mortar will protect or harm your brickwork.

Strength (Match or Slightly Softer)

The mortar should be no stronger—and ideally slightly weaker—than the brick it surrounds. This ensures that any movement, settlement, or thermal stress is absorbed by the joint rather than transferred to the masonry face. Compressive strength testing on small samples can confirm the match, but experienced contractors often assess this through visual inspection and simple field tests on the existing mortar.

Permeability (Safe Vapor Exchange)

Brick walls breathe. Moisture enters from rain, condensation, and rising damp, then exits as vapor through the joints and brick face. A compatible mortar allows this exchange to happen safely. Dense, cement-heavy mixes create a vapor barrier that traps moisture inside the wall, where it causes freeze damage in winter and salt migration year-round.

Lime-based mortars—whether natural hydraulic lime or blended mixes—generally offer the permeability historic walls need. The GSA's technical guidance on repointing with lime mortar provides detailed specifications for different exposure conditions.

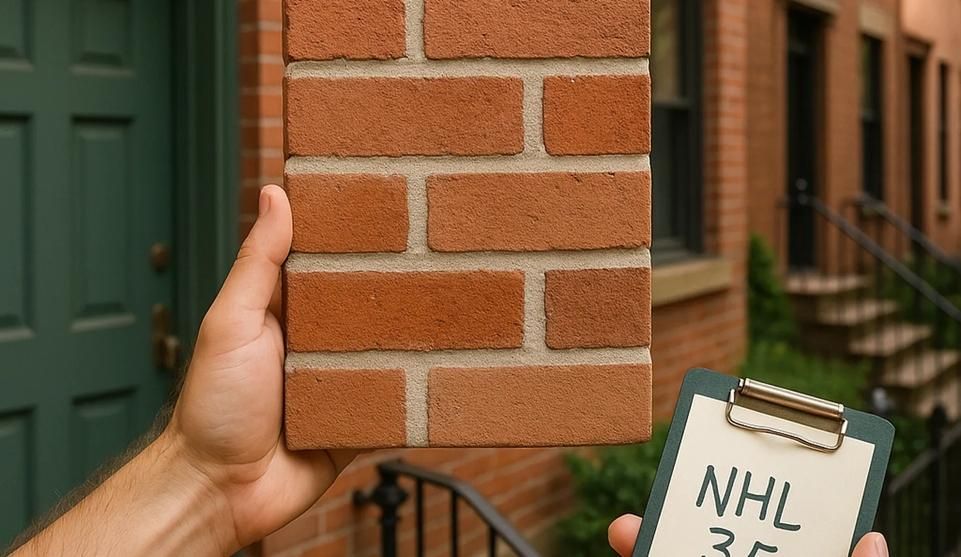

Texture & Color (Sand Gradation and Binder Hue)

Color gets most of the attention, but texture often has the bigger visual impact. The aggregate's particle size, shape, and distribution affect how the joint reads in daylight. A perfectly color-matched mortar with the wrong aggregate texture will still look wrong from across the street.

Sand gradation, binder color (the tone of the lime or cement paste), and any added pigments all contribute to the final appearance. This is especially true on Brooklyn's brownstone-front rowhouses, where façades are closely viewed from the stoop and street level. A mortar that looks acceptable in a bucket can read completely differently once it catches morning or afternoon light on the wall.

Joint Profile & Tooling (How the Wall Reads from the Street)

The joint finish you choose influences both appearance and performance. Weather-struck joints (angled to shed water), flush joints (level with the brick face), and concave joints (slightly recessed and rounded) each cast different shadows and highlight different aspects of the brickwork.

Original joints were tooled to a specific profile for good reason—matching that profile honors the building's character and ensures water is directed away from vulnerable surfaces. Guessing at the wrong profile or applying an overly deep recess can change how the entire façade appears and how well it sheds rain.

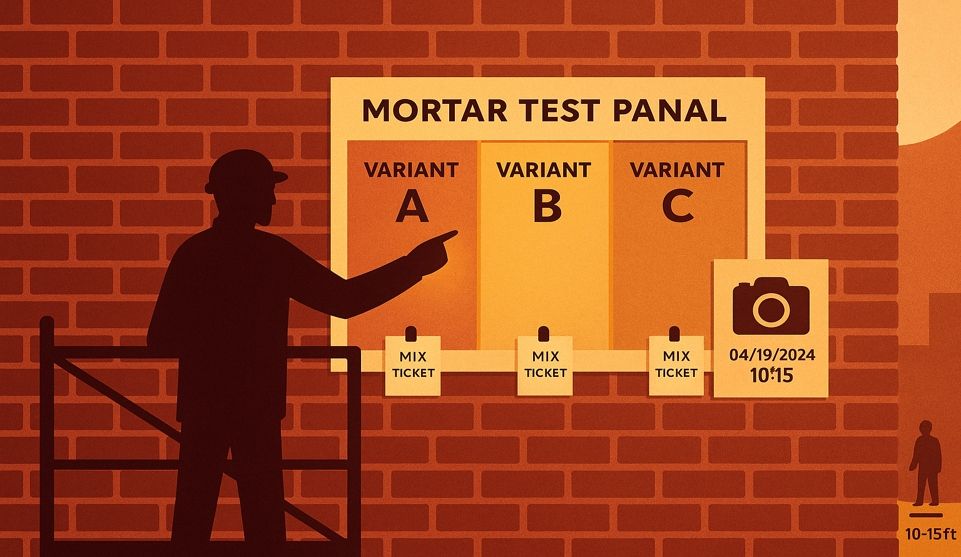

Test Panels = The Paint-Swatch Moment

Before committing to full-scale work, contractors prepare small trial areas—typically one or two square feet in an inconspicuous location. These test panels serve the same function as paint swatches: they let you evaluate the final appearance under real conditions before making an irreversible choice.

Reviewing a test panel isn't a quick glance. Check it at three distances: up close (within a foot), from a typical viewing distance (six to eight feet), and from across the street. Each perspective reveals different aspects of the match. Inspect the panel in varied light throughout the day—morning sun, midday brightness, and late-afternoon shade all change how the mortar reads.

Confirm the texture and tooling, not just the color. Photograph the approved panel with surrounding original joints in the frame for reference. Record the mix proportions, joint type, and weather conditions at the time of installation. This documentation becomes your baseline for the full project and helps ensure consistency across different work phases.

Test-Panel Review Checklist

- Review at three distances: 1 foot / 6–8 feet / street view

- Check in varied light: morning / midday / late-day shade

- Confirm texture and tooling, not just color

- Photograph with context (include adjacent original joints)

- Record mix, joint type, and conditions for sign-off

How We Approach Mortar Matching

The process begins with careful inspection. Understanding the existing mortar's composition, the brick's condition, and the wall's exposure helps guide mix design. Small trials allow for adjustments before larger commitments.

Once an approved sample is documented, the actual repointing work proceeds methodically. Joints are hand-raked or carefully cut to the appropriate depth—typically two to three times the joint width—to remove deteriorated material without damaging sound brick edges. The cavity is cleaned, dampened to control suction, and filled with the approved mix in layers that are properly compacted and tooled to match the original profile.

Final clean-down removes any mortar residue from brick faces, and protection measures (such as breathable sheeting during curing) ensure the work sets properly. For more detail on different mortar formulations and their applications, see Understanding Different Mortar Types for Your Period Home's Brickwork.

Compatibility Triangle (Mortar-First Litmus)

- Strength: Match or be slightly softer than the original brick

- Permeability: Allow safe vapor exchange; avoid moisture trapping

- Texture & Color: Aggregate size, sand tone, binder hue

- Joint Profile & Tooling: Weather-struck, flush, concave—match original look

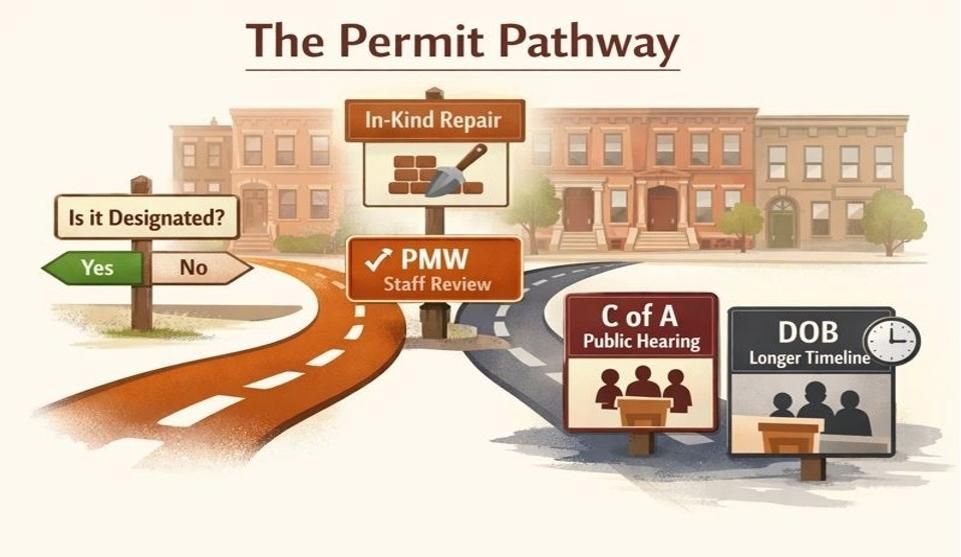

NYC/LPC Basics

Properties within New York City's historic districts typically require Landmarks Preservation Commission approval for exterior work, including brick pointing. Repointing is usually eligible for staff-level review when the scope is limited to in-kind repairs with compatible materials.

Good documentation accelerates the process. Clear photographs showing the existing conditions, written descriptions of the proposed work, and—when required—samples or test-panel images help reviewers understand the project quickly. Homeowners in landmark districts should confirm specific requirements with LPC before starting work. The LPC Permit Guidebook outlines the process and necessary submissions.

For perspective on common pitfalls during historic repointing, Common Brick Pointing Mistakes That Can Harm Your Historic Home addresses frequent missteps and how to avoid them.

What to Expect On-Site (Dust, Noise & Access)

Repointing generates controlled dust and brief periods of noise during joint raking. Containment measures—plastic sheeting, misting, and HEPA filtration where appropriate—minimize airborne particles. Hand tools and low-impact mechanical methods reduce vibration and protect adjacent masonry.

Sequencing matters. Working section by section rather than across the entire façade at once keeps disruption manageable and allows for quality control at each stage. Daily cleanup removes debris and maintains site safety for neighbors and pedestrians—particularly important on Brooklyn's narrow sidewalks and stoops.

Scaffolding or lift access may be necessary depending on the building height. Coordination with adjacent properties is standard practice when working on shared party walls or where equipment must be positioned near property lines. Communication with neighbors about timing, duration, and expected impacts helps the project proceed smoothly.

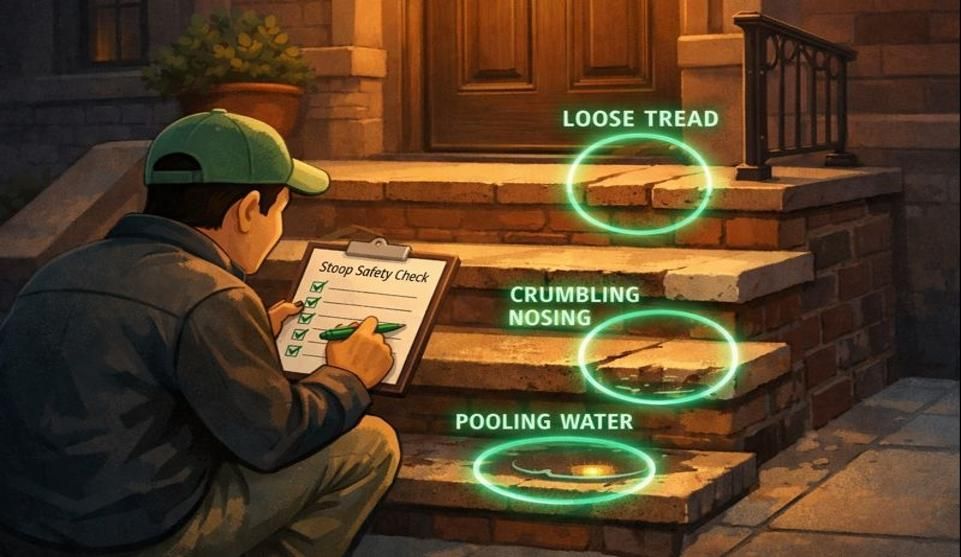

Adjacent masonry concerns—such as lintel replacement or parapet wall reconstruction—are sometimes identified during repointing inspections. Brooklyn townhouses frequently feature painted lintels, parapets, and stoops where careful repointing reduces water entry at steel and parapet returns. Addressing these issues together can be more efficient than staging separate projects.

Moisture management extends beyond the joints themselves. If persistent dampness from below is contributing to joint deterioration, foundation waterproofing may be a worthwhile parallel investment to protect the entire masonry envelope.

Frequently Asked Questions

What does "compatible mortar" actually mean?

A mix that matches the original brickwork in strength, permeability, texture, and color so it seals out water without stressing the brick.

Is "tuckpointing" the same as repointing?

In common usage, yes. Historically, "tuckpointing" refers to a specific decorative finish technique where thin ribbons of contrasting mortar are applied over flush joints. For standard repairs, the term "repointing" more accurately describes the work—removing deteriorated mortar and refilling the joints with a compatible mix.

Do I need an LPC permit to repoint in a historic district?

Most exterior work in historic districts requires LPC approval. Repointing is typically eligible for staff-level review with proper documentation—photographs, scope description, and sample approvals.

How long should quality repointing last?

Done correctly with compatible materials, decades. Well-executed repointing often lasts thirty years or more, depending on exposure and ongoing maintenance.

Will the work be dusty or noisy?

Expect controlled dust and brief noise during joint raking. Containment, sequencing, and daily cleanup minimize impact to neighbors.

Why do sample or test panels matter?

They align expectations on color, texture, and joint finish before full-scale work, reducing rework and delays. A test panel approved in daylight at multiple distances becomes the standard for the entire project.

Next Steps

Understanding compatibility is the foundation. Seeing it demonstrated on your own façade—through carefully prepared test panels reviewed in real light—turns theory into confidence.

For more context on why the right mortar mix is critical for Brooklyn's historic brick, see Why the Right Mortar Mix is Everything for Historic Brooklyn Brick.

If you're ready to explore what compatible repointing looks like for your home, we invite you to see Brooklyn test-panel photos or request a 15-minute mortar-matching walkthrough. Visit the Contact page to discuss your brick pointing goals with our team.

You can also connect with us through our Google Business Profile or reach out directly at Masonry Contractor in Brooklyn, NY to learn more about our approach.

Disclaimer

General information for historic brick repointing in NYC. Properties in historic districts typically require LPC approvals; confirm project-specific requirements with LPC and your contractor.

Our Editorial Process

This article follows City Suburb Inc's preservation-first editorial standards, checked against authoritative guidance (NYC LPC, NPS, GSA). No unverified claims or speculative numbers.

Author Byline & Bio: City Suburb Inc Preservation Team — Masonry and façade restoration specialists serving Brooklyn & NYC. We prioritize compatible materials, small on-wall trials, and neighbor-friendly execution.